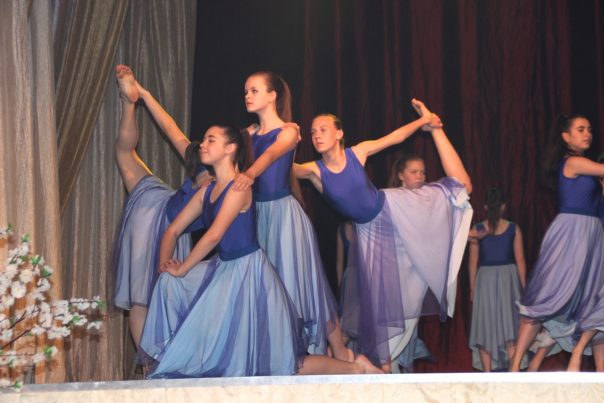

Ансамбль современной хореографии «Всплеск»

Ансамбль современной хореографии «Всплеск» был создан в феврале 2016 года. В коллективе занимаются дети от 3-х до 17 лет. Руководит коллективом яркий, самобытный, талантливый педагог — Анастасия Сергеевна Шульгина.

Дети с удовольствием осваивают азы классического танца, танцевальной акробатике и современной хореографии (contemporary и джаз-модерн)

Репертуар «Всплеска» состоит из композиций, решенных языком современной хореографии, а также включает в себя детский эстрадный танец, хореографические миниатюры и мини-спектакли.

В репертуаре ансамбля более 40 разнохарактерных современных композиций, отвечающих критериям художественности. Ансамбль обладает отличительным исполнительским мастерством, его репертуар отличает содержательность, самобытность, образность и разнообразие танцевальной лексики. Предпочтение воспитанники отдают эстрадной (современной) хореографии. Коллектив постоянно работает над пополнением и обновлением своего репертуара новыми постановками.

Требовательность к себе, высокий художественный вкус их руководителя, позволили ансамблю, неоднократно становится лауреатами и дипломантами различных конкурсов, смотров, фестивалей. Покорили Санкт-Петербург, Москву, Казань и Екатеринбург.

Самобытные костюмы, завораживающие сюжеты, легкость и слаженность во всем – визитная карточка ансамбля современной хореографии «Всплеск».

Ансамбль современной хореографии «Всплеск» – это сплоченный коллектив педагогов, детей и родителей. Концертные выступления, развлекательные мероприятия, творческие встречи и поездки – все это создает благоприятную атмосферу в детском коллективе. На сегодняшний день, ансамбль «Всплеск» – один из интересных и перспективных творческих коллективов учреждения.

I blog frequently and I really appreciate your content. Your article has really peaked my interest. I will book mark your blog and keep checking for new details about once per week. I opted in for your RSS feed too.

Sweet website , super layout, really clean and utilize genial .

Nice post. I learn something new and challenging on sites I stumbleupon on a daily basis. It will always be interesting to read content from other writers and use a little something from their sites.

We are a group of volunteers and starting a new scheme in our community. Your website provided us with valuable info to work on. You’ve done a formidable job and our whole community will be thankful to you.

You have brought up a very excellent details , thankyou for the post. “Beginnings are apt to be shadowy and so it is the beginnings of the great mother life, the sea.” by Rachel Carson.

You should be a part of a contest for one of the best blogs on the net. I’m going to recommend this website!

cleaning supplies should have earth friendly organic ingredients so that they do not harm the environment;;

Normally I don’t read article on blogs, but I wish to say that this write-up very forced me to check out and do it! Your writing style has been amazed me. Thanks, very nice post.

разработка сайтов https://seo-5.ru

pay per click programs are really great, i could earn some decent cash from it..

I always visit new blog everyday and i found your blog.;”\»”`

Very good info. Lucky me I found your site by accident (stumbleupon). I have bookmarked it for later!

If only my personal content articles appeared as if this particular! That is a enhance, btw?-I ‘m new to blog posting and reading numerous blog posts is helping me out with my very own. Any kind of info you could throw my method to assistance is very appreciated. Just good information on this particular post!

You got a very good website, Gladiola I discovered it through yahoo.

My brother suggested I might like this blog. He was totally right. This post actually made my day. You cann’t imagine simply how much time I had spent for

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники в челябинске

I just added this site to my rss reader, great stuff. Can’t get enough!

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание — сервисный центр в челябинске

Hello! I simply wish to make a huge thumbs up for any wonderful information you’ve here for this post. I’ll be coming back to your site to get more detailed soon.

Если вы искали где отремонтировать сломаную технику, обратите внимание — профи услуги

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники в барнауле

Если вы искали где отремонтировать сломаную технику, обратите внимание — сервис центр в барнауле

It’s quite hard to find a good site. And I think I am lucky enough to have come here. The posts are doing great and full of good insights. I would be glad to keep on coming back here to check for updates!

Hey, great blog you have here, think I came across it on Yahoo but im not sure nowanyway, Ill check back again! Are guests allowed to post here?

Good aftie, i am a blogger too” and i can see that you are a nice blogger too,

vibration analysis

The Value of Vibration Mitigation Systems in Machinery

Across industrial settings, devices along with rotational machinery serve as the foundation of production. However, a of the most widespread challenges which could obstruct the functionality along with durability exists as vibration. Resonance can result in a series of issues, including lowered precision along with productivity leading to elevated wear and tear, in the end bringing about pricey interruptions along with maintenance. This is where vibration management tools becomes critical.

Why Vibration Control proves Crucial

Oscillation in equipment can lead to numerous detrimental effects:

Minimized Production Performance: Excess vibration may bring about imbalances and imbalance, lowering overall productivity in the machinery. This might cause slower manufacturing speed and increased energy use.

Heightened Deterioration: Continuous resonance hastens overall wear and tear to equipment components, leading to more regular servicing and the risk for unanticipated unexpected issues. Such a scenario not only heightens production expenses but also decreases the durability in the existing systems.

Protection Risks: Unchecked resonance could bring significant safety concerns both to both the machinery and the operators. In extreme situations, extreme situations, this can bring about disastrous machinery failure, endangering operators and resulting in considerable damage in the premises.

Exactness as well as Quality Challenges: For businesses where demand high precision, such as manufacturing and aviation, oscillations can lead to discrepancies with the production process, leading to flawed products along with increased waste.

Reasonably Priced Solutions towards Vibration Regulation

Putting money in resonance control systems proves not only essential but a smart decision for any business any industry involved with mechanical systems. We offer modern vibration management systems work to engineered to eliminate vibrations in various equipment and spinning equipment, guaranteeing uninterrupted and effective performance.

What differentiates our equipment apart is its economic value. We understand the significance of cost-effectiveness in the modern competitive marketplace, which is why we offer high-quality vibration management solutions at costs that won’t break the bank.

Through selecting these tools, you’re not only protecting your machines along with improving its operational effectiveness but also putting resources towards the enduring achievement of your company.

Final Thoughts

Vibration control is an essential component in preserving the effectiveness, safety, as well as longevity of your machines. Using these reasonably priced vibration control equipment, it is possible to make sure your operations run smoothly, your products are of high quality, along with your workers stay safe. Do not permit vibration compromise your operations—put money in the appropriate systems today.

You ought to take part in a tournament first of the highest quality blogs on-line. I will suggest this website!

ремонт телевизоров недорого

Fashion Courses Online… […]here are some links to sites that we link to because we think they are worth visiting[…]…

When I originally commented I clicked the -Notify me when new comments are added- checkbox now every time a comment is added I get four emails concentrating on the same comment. Can there be by any means you are able to remove me from that service? Thanks!

ремонт телевизоров в москве

I must examine with you here. Which isn’t one thing I often do! I get pleasure from reading a post that may make individuals think. Also, thanks for permitting me to remark!

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники

ремонт телевизоров недорого

сколько стоит ремонт телевизора плазма

Если вы искали где отремонтировать сломаную технику, обратите внимание — профи челябинск

Thank you for your very good information and feedback from you. car dealers san jose

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники в челябинске

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт техники в барнауле

Если вы искали где отремонтировать сломаную технику, обратите внимание — техпрофи

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт бытовой техники

Если вы искали где отремонтировать сломаную технику, обратите внимание — ремонт техники в барнауле

заказать создание сайтов москва недорого продвижение сайта

It can be in no way also late to mend.

Hello! I just now would like to offer a huge thumbs up for the wonderful info you might have here on this post. I am returning to your website for additional soon.

ремонт телевизора на дому в москве

of course, diamond rings would always be the best type of wedding rings that you can give your wife”

vibration analysis

The Significance of Vibrations Regulation Apparatus in Mechanical Systems

In manufacturing sites, equipment along with rotating systems are the foundation of manufacturing. Yet, one of the commonly prevalent concerns which can impede the operation and longevity exists as oscillation. Vibrations could lead to a array of complications, including lowered precision along with productivity leading to increased damage, finally leading to high-cost downtime as well as fixes. This is when resonance control apparatus proves to be vital.

Why Oscillation Control proves Necessary

Vibration in equipment can cause multiple negative impacts:

Lowered Operational Productivity: Excess vibration might result in misalignment along with imbalance, decreasing the effectiveness in the devices. Such a scenario may bring about slower output times and elevated energy use.

Greater Deterioration: Constant vibrations accelerates total deterioration in machine components, bringing about increased servicing as well as an possibility for unanticipated unexpected breakdowns. Such a scenario not only raises maintenance expenses as well as decreases the lifetime for your systems.

Protection Hazards: Excessive vibration can pose considerable security risks for the machinery and the machines as well as the operators. In, severe cases, it could bring about devastating system collapse, threatening operators and leading to widespread devastation across the premises.

Accuracy as well as Production Quality Concerns: In fields where rely on precise production, for example manufacturing and aerospace, vibration may lead to inaccuracies during the manufacturing process, producing faulty goods as well as increased waste.

Cost-effective Alternatives for Vibration Regulation

Investing in oscillation control tools remains not just a necessity and also a smart decision for any business that relies on machinery. We offer advanced vibration control systems are designed to engineered to reduce vibrations within any machinery as well as rotating equipment, ensuring smooth and efficient operations.

What distinguishes these tools apart is its economic value. We understand the significance of affordability in today’s competitive market, and for that reason our offerings include premium oscillation control tools at pricing that are reasonable.

Opting for these tools, you’re not only preserving your machines and increasing its efficiency but also investing into the long-term performance of your business.

Conclusion

Vibration management proves to be an essential factor in ensuring the effectiveness, safety, as well as lifetime of your machines. With these reasonably priced oscillation control systems, one can be certain your operations run smoothly, your products maintain top quality, and your workers stay secure. Never permit resonance affect your operations—invest in the correct apparatus today.